|

|||

|

NOTICE: These parts are not PMA'd! You and your IA will need to decide whether these

meet the requirements of owner-produced parts for installation on your airplane.

If you have arrived on this page as a result of a part number (0517039-2) or nomenclature search then...

The Handles are FINALLY available!

It has been pointed out that aftermarket door handles from 1962 Mercury Comets will work on the Cardinal. While it is true that they will fit, I recommend skipping that particular shortcut because the versions commonly available on the internet (~$26) have a cheap pot metal spline which will strip in about 5 uses. This is not a part that you want to fail in the event of the necessity of a rapid egress from a burning airplane. A replacement certified handle is available from Macfarlane (search part number MC0711861-1) The price of them on Aircraft Spruce as of 09 November 2025, was $258 each plus shipping.

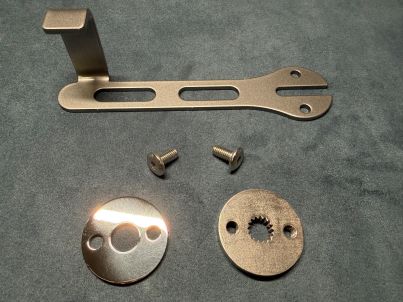

My design consists of 1) Spline, 2) Handle, 3) Cover, and 4) Bolts.

The Handle, Spline, Cover, and bolts are made of 304 stainless steel.

There are several advantages to this design including:

A.) It's easier to install and remove. The stock handle has a very tricky

little clip shown here.

.jpg)

.jpg)

B.) It gives you more leg space in the cabin.

C.) It provides more leverage. Because the tab is a full six inches from the point of rotation, it can be closed with two finger tips.

D.) It's lighter (I was shocked too when I put them on the scale).

E.) It's custom-orderable. By default the Handles are powder coated in metallic grey and the Covers are polished on one side. If you would like the Handles powder coated in a different color, that's available but it will entail a slight shipping delay and a modest upcharge. Alternate colors available are: Semi-Gloss Textured Black, Gloss Black, Matte Black, Wrinkle Black, Gloss Grey, Gloss White, Gloss Blue, Gloss Green, Gloss Red, and Gloss Yellow. If you want a color not listed here - or bare stainless - please contact me. Similarly if you want the Cover done in some other finish than polished, please contact me. I will be investigating a brushed look but those are not yet available. If you think that would be better than polished, again, please let me know and I'll pursue it more diligently.

Closed Open

Here's a close up view of the back of the Spline with the bolts fully tightened. You can see that they do not extend beyond the back of the Spline and so won't wear grooves in your washer or placard.

If you'd like to check out the installation instructions before buying, please find them here.

Price: $100.00 Each, $200.00 per pair (Free shipping to the 48 states. For shipping outside of the Continental US, please contact me first. I will only charge actual cost.)

Return policy: If returned unmodified within 180 days from your order, I will refund 100% of your purchase price. If you want to return the parts after 180 days, please contact me.

How to pay: PayPal (username "mjparry@verizon.net") or check payable to: Matt Parry, 531 Geranium Pl, Oxnard, CA 93036

All parts are made in the USA out of 304 stainless steel except the bolts, which are from China.

.jpg)